-

-

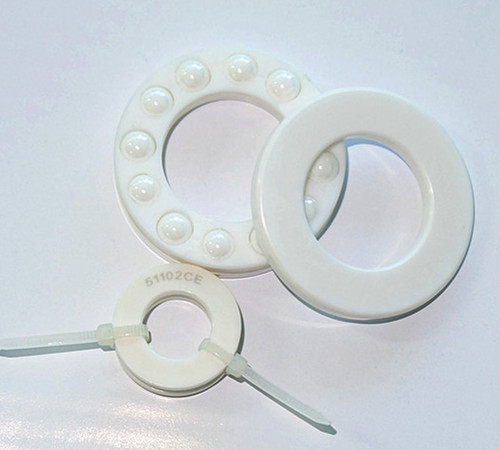

Product name: ceramic thrust ball bearings

-

-

Price: ASK

-

-

Post date: 2016-12-16

-

-

Stock Quantity: 1000

-

Introductions:

Full ceramic bearing ZrO2 material

Full ceramic bearing ZrO2 material has great property such like suitable for low and high temperatures, high load capacity, corrosion resistance, nonmagnetic insulated and self lubrication. Thus it suit for the specific applications which are not available for bearing steel and hybrid construction ceramic ball bearing materials.

Full ceramic bearing Si3N4 material

Full ceramic

bearing Si3N4 material has similar property as ZrO2

material, In addition; it has lower weight , better wear resistance, high hardness, and it can bear higher temperature than ZrO2 material.

Structure:

Rings(ZRO2/SI3N4)+ Retainer(PEEK/PTFE/NYLON)+Ball( ZRO2/SI3N4)

Performance:

1. Anti-rust and corrosion

2. Anti-high temperature

3. Wear-resistance

4. Self-lubrications

5. Without magnetism

Applications :

Chemistry Industry; Medical Feld; food Machinery; Printing Machinery; Electronic Equipment; petroleum Industry and Space technology ect

Packing:

Vacuum Packing and Single box packing

| Thrust ball ceramic bearings table size | ||||||||

| Dimensions (mm) | Mounting Dimensions(mm) | Weight(kg)(ref.) | ||||||

| item | d | D | T | r(min) | d1 max | D1 min | ZrO2 | Si3N4 |

| 51100CE | 10 | 24 | 9 | 0.3 | 24 | 11 | 0.015 | 0.0078 |

| 51200CE | 26 | 11 | 0.6 | 26 | 12 | 0.022 | 0.011 | |

| 51101CE | 12 | 26 | 9 | 0.3 | 26 | 13 | 0.016 | 0.009 |

| 51201CE | 28 | 11 | 0.6 | 28 | 14 | 0.024 | 0.013 | |

| 51102CE | 15 | 28 | 9 | 0.3 | 28 | 16 | 0.018 | 0.0094 |

| 51202CE | 32 | 12 | 0.6 | 32 | 17 | 0.033 | 0.018 | |

| 51103CE | 17 | 30 | 9 | 0.3 | 30 | 18 | 0.019 | 0.01 |

| 51203CE | 35 | 12 | 0.6 | 35 | 19 | 0.038 | 0.021 | |

| 51104CE | 20 | 35 | 10 | 0.3 | 35 | 21 | 0.028 | 0.015 |

| 51204CE | 40 | 14 | 0.6 | 40 | 22 | 0.059 | 0.032 | |

| 51105CE | 25 | 42 | 11 | 0.6 | 42 | 26 | 0.043 | 0.023 |

| 51205CE | 47 | 15 | 0.6 | 47 | 27 | 0.085 | 0.046 | |

| 51106CE | 30 | 47 | 11 | 0.6 | 47 | 32 | 0.049 | 0.026 |

| 51206CE | 52 | 16 | 0.6 | 52 | 32 | 0.11 | 0.056 | |

| 51107CE | 35 | 52 | 12 | 0.6 | 52 | 37 | 0.062 | 0.033 |

| 51207CE | 62 | 18 | 1 | 62 | 37 | 0.16 | 0.086 | |

| 51108CE | 40 | 60 | 13 | 0.6 | 60 | 42 | 0.092 | 0.049 |

| 51208CE | 68 | 19 | 1 | 68 | 42 | 0.21 | 0.11 | |

| 51109CE | 45 | 65 | 14 | 0.6 | 65 | 47 | 0.11 | 0.059 |

| 51209CE | 73 | 20 | 1 | 73 | 47 | 0.24 | 0.13 | |

| 51110CE | 50 | 70 | 14 | 0.6 | 70 | 52 | 0.12 | 0.063 |

| 51210CE | 78 | 22 | 1 | 78 | 52 | 0.29 | 0.16 | |

| 51111CE | 55 | 78 | 16 | 0.6 | 78 | 57 | 0.17 | 0.093 |

| 51211CE | 90 | 25 | 1 | 90 | 57 | 0.46 | 0.25 | |

| 51112CE | 60 | 85 | 17 | 1 | 85 | 62 | 0.22 | 0.12 |

| 51212CE | 95 | 26 | 1 | 95 | 62 | 0.52 | 0.28 | |

| 51113CE | 65 | 90 | 18 | 1 | 90 | 67 | 0.25 | 0.13 |

| 51213CE | 100 | 27 | 1 | 100 | 67 | 0.58 | 0.31 | |

| 51114CE | 70 | 95 | 18 | 1 | 95 | 72 | 0.27 | 0.14 |

| 51214CE | 105 | 27 | 1 | 105 | 72 | 0.61 | 0.33 | |

| 51115CE | 75 | 100 | 19 | 1 | 100 | 77 | 0.3 | 0.16 |

| 51215CE | 110 | 27 | 1 | 110 | 77 | 0.65 | 0.35 | |

| 51116CE | 80 | 105 | 19 | 1 | 105 | 82 | 0.32 | 0.17 |

| 51216CE | 115 | 28 | 1 | 115 | 82 | 0.72 | 0.38 | |

| 51117CE | 85 | 110 | 19 | 1 | 110 | 87 | 0.34 | 0.18 |

| 51217CE | 125 | 31 | 1 | 125 | 88 | 0.94 | 0.5 | |

| 51118CE | 90 | 120 | 22 | 1 | 120 | 92 | 0.5 | 0.27 |

| 51218CE | 135 | 35 | 1.1 | 135 | 93 | 1.3 | 0.69 | |

| 51120CE | 100 | 135 | 25 | 1 | 135 | 102 | 0.74 | 0.39 |

| 51220CE | 150 | 38 | 1.1 | 150 | 103 | 1.73 | 0.92 | |

| 51122CE | 110 | 145 | 25 | 1 | 145 | 112 | 0.8 | 0.43 |

| 51124CE | 120 | 155 | 25 | 1 | 155 | 122 | 0.86 | 0.46 |